Tyvek Coveralls vs. Microporous Coveralls: The Ultimate Guide to Workplace Protection

Tyvek coveralls, crafted from flash-spun polyethylene, deliver unmatched breathability and durability, making them ideal for hot environments and dusty tasks. Microporous coveralls, on the other hand, protect effectively against liquids and particles at a lower cost. While Tyvek reduces heat stress and excels at longevity, microporous designs are more affordable and suitable for moderate risks. By understanding these distinctions, you can confidently choose the right protective clothing for your workplace needs.

Tyvek Disposable Coveralls: Comprehensive Guide for Buyers and Users

Tyvek disposable coveralls provide exceptional protection, durability, and comfort in hazardous environments like healthcare, construction, and chemical handling. Made from flash-spun polyethylene, they block particles, liquids, and biological hazards. Certified to meet safety standards, these coveralls ensure worker safety and hygiene. Designed for single use, they should not be washed or reused.

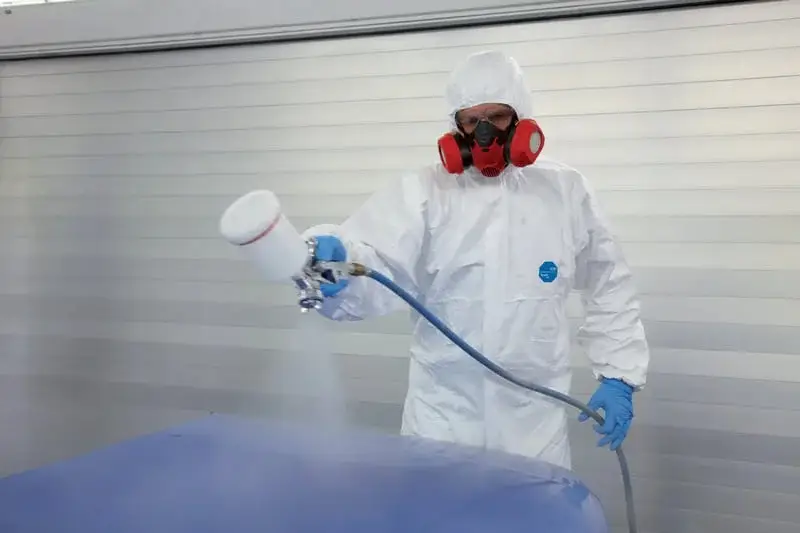

A Complete Buying Guide of Disposable Paint Suits

Disposable paint suits protect workers from paint splashes, chemicals, and dust, ensuring safety and cleanliness in industries like painting, manufacturing, and construction. Made from materials like microporous fabric and Tyvek®, these suits offer durability, breathability, and comfort. Key features include elastic cuffs, hoods, and gusseted crotches. Popular brands include 3M, DuPont, and Morntrip. Choose suits based on material, cost, and usage scenarios to ensure optimal protection and efficiency.

A Comprehensive Guide to Disposable Medical Coveralls

Disposable medical coveralls are essential for infection control and safety across industries. This article highlights their market growth, material types, regulatory compliance, and purchasing benefits, emphasizing their cost-effective and protective advantages.

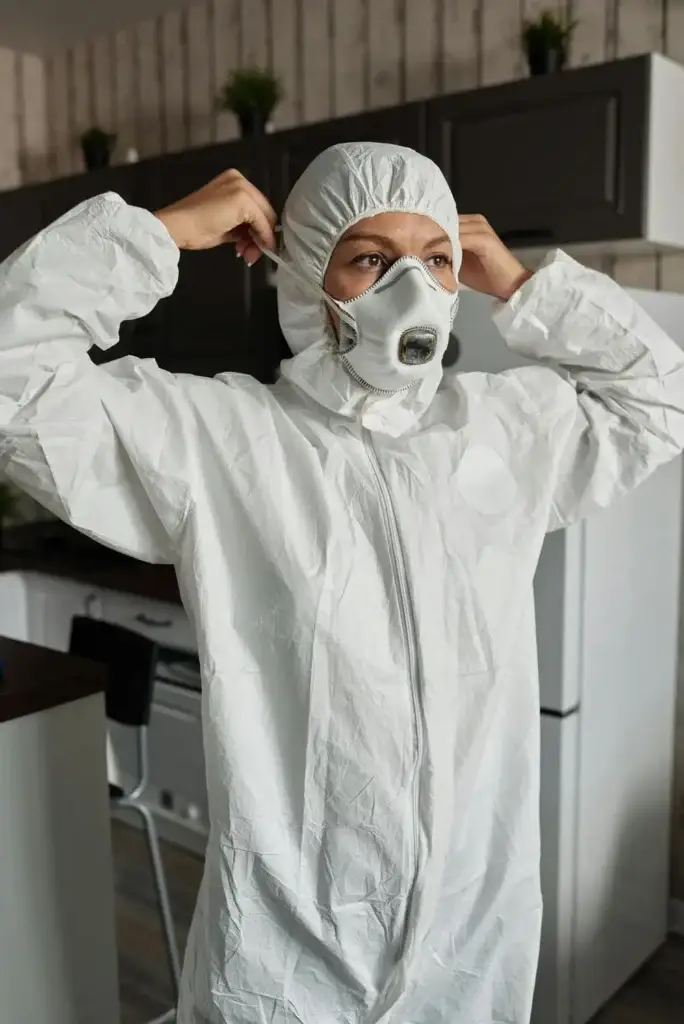

How To Wear And Remove Disposable Coveralls

Disposable coveralls provide essential protection in hazardous environments. Proper wearing and removal are crucial to prevent contamination and maximize safety. Steps include inspecting coveralls, ensuring a secure fit, donning additional PPE, and carefully removing and disposing of coveralls to avoid cross-contamination. Following these guidelines ensures hygiene, safety, and compliance in high-risk workplaces.

What Are Type 5 6 Coveralls?

Type 5 6 coveralls provide essential protection in hazardous environments, with Type 5 blocking solid particles and Type 6 guarding against liquid splashes. Certified to EN ISO 13982-1 and EN 13034 standards, these coveralls offer durability, breathability, and comfort for industries like construction, healthcare, and manufacturing. Proper selection ensures compliance, safety, and productivity.

Can You Wash Disposable Coveralls

Disposable coveralls are designed for single use and cannot be washed without compromising their protective properties. Washing weakens the material, damages protective barriers, and increases health and contamination risks. Proper decontamination methods, such as brushing or light rinsing, may reduce surface contaminants but do not restore usability. For optimal safety, disposable coveralls should be disposed of after use, adhering to regulatory standards.

Where to Buy Disposable Coveralls

Disposable coveralls are essential for safety across industries like healthcare, construction, and food processing. This guide outlines key materials (polypropylene, SMS, microporous fabric), features like comfort and protection, and certifications (EN 14126). It also highlights top suppliers like Morntrip, Amazon, and Home Depot, offering diverse options for bulk and individual purchases. Buyers can request samples to ensure fit and quality. Choosing the right coveralls ensures safety, compliance, and cost-effectiveness.

Comprehensive Guide To Microporous Coveralls: Features, Applications, And Trends

Microporous coveralls are vital PPE offering lightweight, breathable protection against liquids, dust, and hazardous materials. Designed for industries like healthcare, construction, and pharmaceuticals, they meet strict safety standards such as Type 5/6 and EN certifications. Key features include attached hoods, storm flap zippers, and elastic cuffs for enhanced safety and comfort. Market growth is driven by infection control, workplace safety regulations, and eco-friendly innovations, making these coveralls indispensable for maintaining hygiene and compliance.

What Are Disposable Coveralls Made Of ?

The blog explains the various materials used for disposable coveralls, such as polypropylene, SMS, PP+PE, microporous fabric, and Tyvek®. It highlights their unique properties, such as breathability, liquid resistance, and particulate protection, and discusses their applications in medical, industrial, and construction environments. Key factors like work environment, breathability, and protection levels are emphasized to help users choose suitable coveralls. Morntrip offers customizable, high-quality disposable coveralls tailored to diverse industry needs.