Table of Contents

Personal Protective Equipment (PPE) is essential for ensuring safety across various sectors by protecting against specific hazards. In healthcare, PPE like gloves, masks, gowns, and face shields safeguard workers from infectious agents and hazardous chemicals. In construction, hard hats, steel-toed boots, and high-visibility clothing protect against physical injuries and respiratory hazards. In manufacturing, safety gear such as gloves, safety glasses, and hearing protection prevent injuries from machinery and exposure to toxic substances. Across these industries, PPE is crucial for maintaining a safe working environment, minimizing risks, and ensuring the well-being of workers.

Why Choose PPE Suppliers in China?

China is a major hub for PPE production and supply due to its extensive manufacturing infrastructure, cost efficiencies, and rapid scalability. In 2020, China had over 55,000 manufacturers producing PPE, including masks, protective clothing and gloves. The country supplied approximately 50% of the world’s PPE in 2020 alone. From 2019 to 2022, China’s PPE exports consistently comprised over 40% of the global market, underscoring its dominance.

China’s highly developed logistics network ensures swift delivery times. The cost advantage is significant, with Chinese PPE often costing 30-50% less than those from other regions due to lower labor and production costs.

By choosing PPE suppliers in China, buyers benefit from reliable supply chains, competitive pricing, and quick delivery, making it an optimal choice for ensuring PPE availability during global crises.

Finding Reliable PPE Suppliers

1. Researching PPE Manufacturers.

Finding reputable PPE safety suppliers can be streamlined through online directories, trade shows, and industry networks. Here are some tips:

Online Directories: Use industry-specific platforms such as ThomasNet, Global Sources, or Alibaba. Look for PPE wholesale suppliers with high ratings, positive reviews, and verification badges.

PPE Trade Shows: Attend events like the A+A Trade Fair or the NSC Congress & Expo. These platforms offer direct interactions with PPE suppliers, allowing you to assess their offerings and reliability firsthand.

Industry Networks: Join professional associations like the International Safety Equipment Association (ISEA) or local PPE industry groups. Networking can lead to trustworthy recommendations and insights.

Key qualities to look for in a supplier include:

- Reliability: Consistent delivery times and dependable service history.

- Certification: Compliance with international standards (e.g., ISO, CE).

- Production Capacity: Ability to meet your demand, especially during high-need periods.

By focusing on these aspects, you can ensure a strong, reliable partnership with your PPE suppliers.

2. Evaluating PPE Manufacturers Credentials

Verifying certifications such as ISO, CE, and FDA approvals is crucial to ensure PPE product quality, safety, and compliance with international standards.

- ISO: indicates standardized processes and quality control. For PPE supplies, the most common ISO certification is ISO 13485.

- CE: signifies conformity with European safety standards. For PPE clothing wholesalers in Europe and regions recognizing EU standards, CE Type 4, 5, and 6 certifications are the most frequently referenced. In the PPE surgical mask market, the European EN14683 and American ASTM F2100 standards are the most widely recognized.

- FDA approval ensures the product meets U.S. health regulations. If you are a PPE wholesaler or distributor from the United States seeking to collaborate with Chinese medical PPE manufacturers, the FDA 510(k) certification is an essential requirement you cannot overlook.

Navigating Chinese regulatory standards can be simplified by focusing on key certifications like CCC (China Compulsory Certificate) for safety, SFDA for food and drug safety, and NMPA(CFDA) for medical devices. Understanding these standards ensures compliance and mitigates risks.

Conducting background checks involves verifying business licenses, checking export history, and reviewing legal filings. Reading reviews on platforms like Alibaba, Global Sources, and trade forums can reveal vendor reliability and product performance. Additionally, utilize third-party inspection services to confirm product specs and quality before purchase. This due diligence minimizes risks and ensures the acquisition of reliable products.

Communicating Your Needs to Personal Protective Equipment Suppliers

1. Clear Specifications of your PPE requirements

When working with PPE safety suppliers in China, clearly communicate your Personal Protective Equipment (PPE) requirements. Specify the material (e.g., nitrile gloves, polyester vests) and specific qualities (e.g., flame-retardant, chemical-resistant). Accurately mention the size using standard sizing charts and state the exact quantity needed for each item to ensure an adequate supply.

Additionally, outline any compliance standards (e.g., OSHA, ANSI, ISO). For example, “We require 100 pairs of nitrile gloves, size large, chemical-resistant, compliant with EN 374 standards, and 50 high-visibility polyester vests, size medium, ANSI/ISEA 107-2015 compliant.” Clear communication ensures your PPE supplies meet safety and operational needs.

2. Language and Cultural Considerations

Navigating language barriers with Chinese PPE suppliers requires thoughtful strategies. Use apps like WeChat for easier communication; it offers translation features for real-time conversations. Engage with local content to understand cultural nuances and trends.

Learn basic phrases and etiquette to show respect and openness. In meetings, consider hiring a local interpreter to ensure clarity and avoid misunderstandings. Pay attention to non-verbal cues, as gestures and expressions may differ across cultures. Combining technology with cultural sensitivity builds strong relationships with PPE suppliers, ensuring effective cross-cultural business practices.

Negotiating Terms and Pricing with PPE Wholesale Suppliers

1. Pricing Strategies of PPE Supplies

When negotiating PPE prices while ensuring quality, start by thoroughly researching market rates and competitor offerings. Clearly define your quality requirements and communicate them upfront to establish standards. For example, if you are sourcing disposable medical masks from China, you can specify that the masks must meet EN14683 Type I, II, or IIR standards. Similarly, for disposable medical protective clothing, you can require the products to comply with EN14126 standards.

Long-term or bulk agreements with PPE suppliers offer significant advantages. Bulk ordering reduces manufacturers’ procurement and transportation costs, allowing them to offer lower unit prices. It also enhances production efficiency by maximizing production line utilization and minimizing waste from production switching. This efficiency translates into lower unit costs, benefiting both suppliers and buyers through reduced prices and consistent supply.

Flexible payment terms or favorable delivery schedules can also secure better pricing. Planning purchases ahead and avoiding last-minute orders can help get the best prices from PPE suppliers.

Lastly, verify quality through samples, references, or small trial orders before committing to larger purchases. This approach ensures that cost efficiencies are not achieved at the expense of quality.

2. Payment Terms

As a personal protective equipment supplier with over 20 years of experience in PPE manufacturing and exporting, we commonly use the following three payment methods with our clients:

T/T (Telegraphic Transfer): This method, often called a wire transfer, involves electronically transferring funds directly from the buyer’s bank to the seller’s bank. It’s fast and secure but requires a high level of trust, as payments are made before shipment.

L/C (Letter of Credit): This offers security for both parties. The buyer’s bank guarantees payment upon receipt of complying shipping documents. It reduces risk but can be complex and costly due to banking fees and strict compliance requirements.

O/A (Open Account): This term allows the buyer to receive goods before payment is due, often within 30-90 days. It is highly advantageous for buyers but risky for sellers, requiring them to be confident in the buyer’s creditworthiness.

Each payment method in the PPE industry impacts security, cost, and trust, influencing both parties’ operations. Despite the rising use of O/A (Open Account) payments in this competitive market, this method can strain suppliers’ cash flow, leading them to cut costs in ways that might compromise product quality. If a PPE supplier proactively offers O/A terms, it often indicates a severe lack of orders and potential business instability, suggesting the supplier might not be reliable.

Quality Assurance and Testing PPE Supplies

PPE Factories Inspections

Conducting at least three inspections—pre-production, during production, and before shipment—is crucial to ensure product quality, compliance with specifications, and timely detection of defects. Pre-production inspections verify raw materials and initial setup. During production, inspections help to catch and correct errors early, minimizing waste and delays. Final inspections before shipment ensure that only compliant products reach customers, preventing returns and loss of reputation.

Different inspection methods include:

- Video Inspection: Remote inspection via live-streaming or recorded video, offering convenience and cost savings. During the pandemic, due to various countries’ health policies, video inspections became the most common method for wholesalers to verify PPE suppliers in China. However, this approach has significant limitations. Many smaller suppliers could present a false image by recording videos or live-streaming from their partnered large factories, misrepresenting their actual capacity.

- On-Site Inspection: In-person evaluation at the manufacturing facility to provide a thorough and immediate assessment. China currently offers various visa-free transit policies for citizens of many countries, making international travel increasingly convenient. This has significantly facilitated on-site inspections for PPE wholesalers, allowing them to verify PPE suppliers more effectively and ensure the authenticity of their operations.

- Third-Party Inspection: Independent agencies conduct unbiased evaluations, enhancing credibility and assurance of quality. For example, PPE customers from South America often forego direct visits to China due to the 16-28 hour international flights and associated travel costs. Consequently, numerous agencies in Yiwu, China, offer inspection and quality control services specifically for South American clients, ensuring reliable and trustworthy evaluations without the need for long-distance travel.

Each method has its benefits, and a combination of these can provide a comprehensive quality control system.

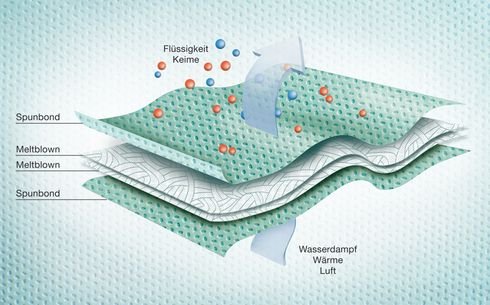

Sample Testing: Using PPE Clothing as An Example

Requesting and evaluating samples before placing a bulk order involves several steps:

Initial Contact: Reach out to the PPE supplier, specify your interest in PPE clothing, and state the required specifications (e.g., XL, blue, SMS fabric).

Sample Request Details: Such as requesting three PPE Clothing samples, discussing costs, and clarifying the shipping method and timeframe.

Evaluation Criteria: Assess quality, durability, and adherence to specifications upon receiving the samples.

Testing: Conduct practical tests, such as checking for wear and tear and assessing comfort during use.

Feedback and Questions: Communicate any concerns or improvements needed to your PPE supplier.

Final Decision: Decide on the bulk PPE order based on your evaluation, ensuring all terms are clear before finalizing.

By following these steps, you can make an informed decision and mitigate risks associated with bulk PPE purchasing.

Logistics and Shipping

1. Incoterms and Shipping Options

Incoterms, or International Commercial Terms, streamline global trade by defining the responsibilities of buyers and sellers. Key terms include:

- FOB (Free On Board): The seller delivers goods onto the ship; the buyer bears costs and risks from that point.

- CIF (Cost, Insurance, and Freight): The seller covers these expenses to the destination port; the buyer handles all subsequent costs and risks.

- DDP (Delivered Duty Paid): The seller delivers goods cleared for import, bearing all costs and risks up to the buyer’s location.

Choosing the best shipping method hinges on cost and delivery time.

- Air freight is the fastest but most expensive, ideal for urgent, small PPE shipments.

- Sea freight is economical for large shipments, though slower, making it a popular choice for bulk PPE suppliers.

- Rail freight offers moderate costs and transit times, suitable for trade with countries along the Belt and Road.

- Courier services are best for small, urgent parcels, often used for trade with neighboring countries like Russia and Vietnam.

PPE Supplies Customs Clearance

Export Process from China

To ensure smooth customs clearance when exporting PPE products from China, prepare the following documentation meticulously:

1. Commercial Invoice: Clearly describe the goods, their value, and the seller/buyer information.

2. Packing List: List the contents, packaging details, and weight.

3. Import/Export Licenses: Necessary permits as per the commodity.

4. Regulatory Compliance Certificates: Such as CE or FDA certification for medical PPE supplies.

5. Medical Device Production License: Certification that the manufacturer is authorized to produce medical devices.

6. Product Test Reports: Verification that the PPE products meet safety and quality standards.

Ensure all documents are accurate and complete to avoid delays during the export process.

Import Process in Destination Country

Upon arrival in the destination country, the following documents are typically required for customs clearance:

1. Commercial Invoice: Must match the details provided to Chinese customs.

2. Packing List: Consistency with the invoice and shipment details.

3. Bill of Lading or Air Waybill: Continued proof of shipment.

4. Import Licenses: Specific to the destination country’s regulations.

5. Certificate of Origin: Verification of manufacturing origin.

6. Regulatory Compliance Certificates: Ensures your PPE orders meet local health and safety regulations (e.g., EN14683 &ASTM F2100 for surgical masks).

By ensuring all documentation is meticulously prepared and staying updated on both Chinese and destination country customs regulations, you can facilitate a hassle-free clearance process for PPE bulk orders.

Building Long-term Relationships

1. Ongoing Communication

Regular communication with PPE suppliers builds trust and transparency, which is crucial for a smooth supply chain. It helps identify and solve problems early, aligns expectations, and reduces misunderstandings. This proactive approach can also improve delivery schedules and terms, mitigating risks and fostering mutual growth.

2. Evaluating Supplier Performance

Regularly assess suppliers using clear KPIs like quality, delivery time, and cost efficiency. Use scorecards to track performance and hold meetings to discuss your PPE bluk order results and feedback. Engage PPE suppliers in planning and innovation, and offer support to meet standards. Prioritize ethical practices to build trust, enhancing reliability and mutual success.

You create a collaborative environment that encourages long-term commitment and continuous improvement by combining rigorous performance assessments with relationship-building efforts. This balanced approach enhances supplier reliability and drives mutual growth and success.

Partnering with reliable PPE suppliers in China ensures you receive high-quality personal protective equipment essential for workplace safety. Our experienced PPE safety suppliers offer competitive prices for bulk orders, allowing you to benefit from cost savings without compromising quality.

As leading PPE wholesale suppliers, we guarantee efficient delivery and exceptional customer service. Our robust supply chain ensures timely procurement, so your safety equipment arrives when needed.

Choose us as your go-to PPE supplier in China for top-notch service and products. Contact us today to secure your bulk order at unbeatable prices and protect your team with the best PPE supplies available. Act now!