Table of Contents

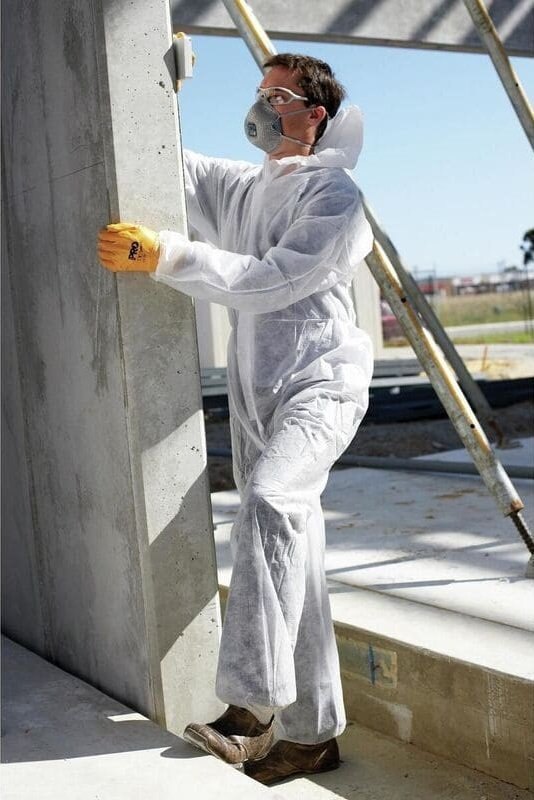

Microporous coveralls are an essential part of personal protective equipment (PPE), offering exceptional safety and comfort in a wide range of working environments. Microporous coveralls have been playing a critical role in industries like healthcare, construction, and manufacturing, because of their wonderfull protection against hazardous materials such as chemicals, pollutants, and biological agents,

Combining lightweight, breathable, and with high durability and protection, microporous coveralls ensure wearer comfort while reducing the risk of occupational accidents and illnesses. Their applications span cleanrooms, petrochemical industries, and agriculture, adhering to stringent safety standards.

The microporous coverall market is growing rapidly, driven by rising healthcare demand, stricter industrial safety regulations, and technological advancements. Key trends include the prioritization of infection control, development of eco-friendly materials, and innovations enhancing comfort and protection. Growth is further fueled by workplace safety initiatives, global health crises like COVID-19, and market expansion in industrializing regions. With increasing awareness of safety standards, microporous coveralls are becoming essential across healthcare, industrial, and emerging markets. This article explores their key features, applications, and market trends, highlighting their indispensable role in safeguarding workers across industries.(GlobeNewswire)

Key Features and Benefits of Microporous Coveralls

Protection Levels of Microporous Coveralls

Most of the microporous coveralls in the market can meet Type 5 and 6 protection standards offer strong barriers against non-hazardous liquids, dust, and particulates. Certified under Category III PPE and comply with EN 13982-1:2004 and EN 13034:2005, these microporous coveralls are perfect for cleanrooms, forensic science, pharmaceuticals, medical settings, and industrial applications where requiring strong barriers from dust and non-toxic liquids.

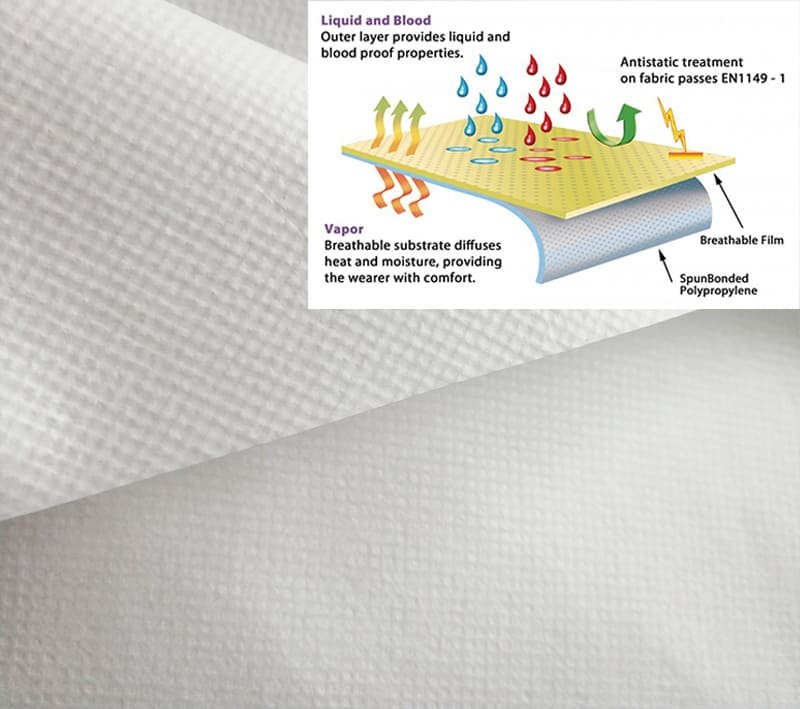

Material Composition

Microporous coveralls are made from a waterproof microporous film and non-woven fabric, hence their durability and lightweight. Their purpose is to create a barrier between radioactive particles and infective agents in compliance to EN 14126, while preventing corrosive substances from entering sensitive areas in accordance with EN 1149-5.

Breathability and Comfort

These coveralls are breathable and lightweight, made from microporous laminate and non-woven fabric for comfort during long wear. The low-lint material reduces contamination risks in clean environments. Features like elastic cuffs and zipped closures ensure a secure, comfortable fit.

Applications of Microporous Coveralls

Microporous coveralls are typically used in environments that demand high levels of protection against various contaminants. Key applications include:

- Construction: Protects workers from dirt, dust, and contaminants on construction sites.

- Pharmaceutical and Food Processing: Guarantees sterility and avoids the risk of cross-contamination during the process and after it when the product is handled.

- Medical and Healthcare: Aimed at the protection against non-hazardous liquids and particulates in the field of medicine.

- Automotive: Assists people who work in the industry’s automotive refinishing when working with sprays, dust, and other chemicals.

- Laboratory and Cleanroom Settings: Prevents exposure and consequent contact with a sterile environment during critical processes.

- Asbestos removal: Protects hazardous asbestos fibers.

- Chemical handling: Protects those at risk from harmful chemicals such as varnishes, resins, or paints.

- Fiberglass handling: Prevents exposure of workers’ skin to harmful fiberglass particles.

- Paint spraying: Prevents exposure to paint and coatings during spray applications.

- Contamination control: Ensures product integrity and safety in controlled environments.

- General maintenance: Protects against dirt, dust, and minor liquid splashes during maintenance tasks.

Design Features of Microporous Coveralls

Microporous coveralls have several design features that improve both protection and comfort. Key elements include:

Attached Hoods and Boots

Hoods and boots are attached to many of these coveralls, which come with protective hoods and boots. These coveralls are quite useful in preventing debris, light liquid splashes, and aerosols from reaching the head and the feet and are thus utilized in industries such as waste cleanup and the automotive finishing industry.

Elasticized Cuffs for Comfort and Safety

Elastic cuffs at the wrists, waist, and ankles are used so that the microporous coveralls may fit tightly. The purpose is so that dangerous micro-organisms or substances do not get inside these coveralls.

Storm Flap Zippers

Some coveralls include storm flap zippers, like those on Jon-Don models, to enhance protection. These zippers prevent substances from entering through the zipper opening, maintaining the integrity of the coverall’s barrier.

These design features ensure that microporous coveralls offer optimal protection while staying comfortable during extended wear.

Market Trends of Microporous Coveralls

The market for microporous coveralls is experiencing robust growth, driven by increasing demand across industries such as healthcare, manufacturing, and construction. The COVID-19 pandemic highlighted their importance in infection control, solidifying their role in healthcare settings. Stricter workplace safety regulations globally have further pushed companies to adopt advanced PPE, including microporous coveralls. Technological advancements have enhanced their design, making them lighter, more breathable, and more comfortable, appealing to a broader range of industries. Additionally, the rising emphasis on sustainability has led manufacturers to explore eco-friendly materials, aligning with consumer preferences and regulatory requirements.

Key Drivers of Market Growth

- Infection Control Needs: Sustained demand in healthcare for preventing hospital-acquired infections (HAIs). (Business Wire)

- Workplace Safety Initiatives: Stricter safety regulations mandate the use of PPE to protect workers.

- Technological Innovations: Advanced materials now offer better protection with added comfort features like antimicrobial coatings.

- Global Health Crises: Events like COVID-19 have expanded demand for disposable protective gear across sectors.

- Emerging Markets Expansion: Rising industrialization in regions like Asia-Pacific and Latin America boosts demand for safety equipment. (Global Growth Insights)

These factors collectively position microporous coveralls as indispensable in ensuring workplace safety and compliance across industries.

Microporous coveralls are indispensable for maintaining safety and compliance across industries, offering reliable protection against hazardous materials while ensuring comfort during extended wear. With their versatile applications in sectors such as construction, healthcare, and pharmaceuticals, these coveralls meet stringent safety standards and support workplace hygiene and efficiency.

At Morntrip, we provide high-quality coveralls tailored to your business needs. With partnerships in over 120 countries and deep expertise in PPE and medical devices, we deliver customized solutions for businesses of all sizes. Contact us today for free samples.