Following this guide, you’ll learn how to find reliable PPE clothing manufacturers in China. This ensures you get high-quality products that improve your business’s reliability and safety. Trust is important when dealing with international PPE suppliers. This guide will help you verify manufacturers, understand necessary certifications, and spot potential problems. These steps will save you time, money, and ensure safety.

By the end of this article, you’ll know how to choose and work with reputable PPE clothing manufacturers, boosting your business’s reputation and reliability. Learn key verification steps, essential certifications, and how to identify red flags to ensure you only work with trustworthy suppliers.

Getting to Know PPE Clothing Manufacturers in China

Diversity and Volume

China’s PPE (Personal Protective Equipment) manufacturing is large and important in the global supply chain. Many factories in China produce a wide range of PPE items like masks, gloves, gowns, and face shields. This variety allows China to meet different industry standards and market needs, from healthcare to industrial safety.

China’s PPE manufacturing sector is known for high-volume production. Advanced technology and a large workforce help factories produce PPE on a large scale. This efficiency ensures a steady supply and quick response to global demand, especially during emergencies like the COVID-19 pandemic. Automation and continuous improvements in manufacturing processes help maintain consistent quality and cost-effective production, making China a key player in the PPE market.

Importance of Verification

Verifying manufacturers is crucial due to varying levels of quality and reliability, especially in critical sectors like PPE (personal protective equipment). The COVID-19 pandemic triggered a sharp increase in PPE manufacturers, particularly in China. This surge arose to meet global demand, but not all manufacturers adhere to stringent safety and quality standards. Effective verification becomes challenging for global buyers when faced with a multitude of new entrants, many of whom may lack proper certification or experience.

Using unverified suppliers can lead to receiving low-quality or fake products, which can be dangerous. Therefore, it’s important to check certifications, request samples, and read reviews to ensure the products meet safety standards. This careful approach helps protect the health of users and the reputation of purchasing organizations.

Types of PPE Clothing Manufacturing in China

Personal Protective Equipment (PPE) clothing is crucial for ensuring safety in various environments. Different types of PPE clothing include:

- Disposable Lab Coats: These are used typically in laboratories to protect against minor spills and contamination.

- Disposable Gowns worn by Medical Personnel: Essential in healthcare settings, these gowns offer protection against infectious agents.

- Disposable Coveralls and Full Body Suits: Designed for protection against chemicals, particulates, or hazardous material handling, ensuring full body coverage.

- Safety Vests: These enhance visibility and provide protection in high-traffic or low-visibility environments, often utilized in construction and roadside works.

- Plastic Aprons: Used primarily for protection against splashes or spills, these are common in medical settings and food processing industries.

Each type of PPE clothing is designed to meet specific safety needs, ensuring the protection and well-being of workers in various fields.

Step-by-Step Guide to Verifying a Safety Clothing Manufacturer

Research and Identify Potential Manufacturers

When looking for reliable PPE clothing suppliers or a good protective clothing manufacturer, it’s important to do thorough initial research. Use online platforms like Alibaba and Made-in-China, which have many listings of manufacturers and suppliers. These platforms provide detailed information on company profiles, product specifications, and customer reviews, helping you make informed decisions.

Additionally, industry directories such as ThomasNet and Global Sources are invaluable resources. They offer categorized listings of manufacturers and suppliers, including detailed descriptions and contact information.

Attending industry-specific trade shows and exhibitions can also be very helpful. Events like the A+A International Trade Fair and the National Safety Council (NSC) Congress & Expo showcase the latest innovations and connect you with leading PPE personal protective clothing suppliers. These gatherings not only provide a firsthand look at products but also offer networking opportunities and insights into industry trends, ensuring you find a supplier who meets your specific needs.

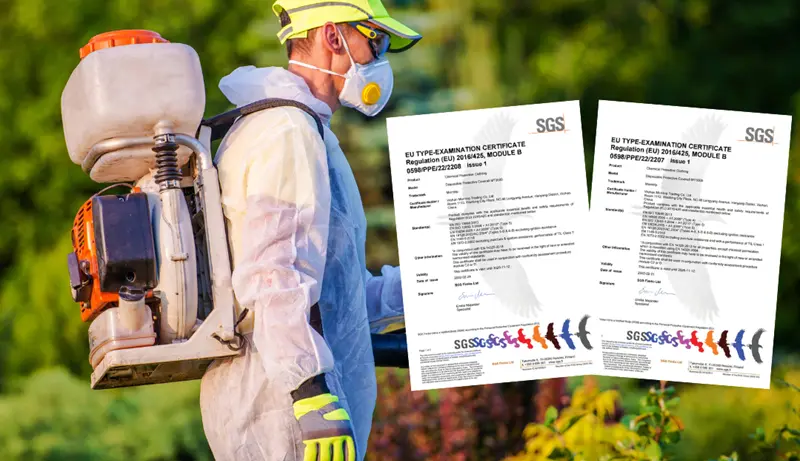

Check Certifications and Compliance

When manufacturing protective clothing or sourcing from personal protective clothing suppliers, it’s crucial to ensure compliance with key international and local certifications. This guarantees safety and quality standards.

Some essential certifications to consider:

- CE: Mandatory for products sold within the European Economic Area.

- FDA: Required for medical devices, including various medical protective clothing, in the United States.

- ISO: Various standards, such as ISO 13688 for protective clothing general requirements.

- NMPA: Certification required for the production and sale of medical devices in China.

Ensuring compliance with these certifications is essential as it guarantees that PPE clothing meets regional safety standards, providing adequate protection for users. Non-compliance can lead to legal issues, penalties, and unsafe products reaching the market.

Common PPE Clothing Production Standards:

1. China Standards

- GB 19082-2009: This is China’s national standard for medical protective clothing. It specifies performance requirements such as impermeability, liquid penetration resistance, and antibacterial liquid penetration.

2. EU Standards

- EN 13795: Requirements and test methods for medical protective clothing used in surgical operations and examinations. It specifies protection performance requirements like impermeability and liquid penetration resistance.

- EN 14126: Specifies protection requirements for protective clothing materials against biological contaminants like bacteria and viruses.

- EN 943-1/2: These standards specify the types, protection performance requirements, and test methods for chemical protective clothing. EN 943-1 is for gas-tight chemical protective clothing, and EN 943-2 is for non-gas-tight chemical protective clothing.

- EN 14605: Used to test the airtight performance of chemical protective clothing.

3. USA Standards

- NFPA 1999: Developed by the National Fire Protection Association, this standard specifies protective performance indicators for medical protective clothing, such as impermeability and liquid penetration resistance.

- ANSI/AAMI PB70: Developed by the American Medical Device Association, this standard is used to evaluate the liquid barrier performance of medical protective clothing.

Evaluate Production Capabilities and Quality Control

Visiting facilities or arranging virtual tours of a Safety Clothing Manufacturer or Protective Clothing Supplier is crucial in ensuring product quality and reliability. Touring the production lines allows you to observe firsthand the materials used and the workmanship involved. This can reveal the manufacturer’s commitment to safety standards and their capability to meet bulk demands.

Assessing quality control processes is equally important. Observing these processes helps verify that the manufacturer has stringent checks in place to detect and rectify defects. This step is essential to ensure the end products meet regulatory requirements and offer maximum protection.

Testing protocols are another key aspect to inspect. Reviewing how safety clothing is tested for factors such as durability, fire resistance, and chemical resistance can provide confidence in the product’s effectiveness.

Collectively, these steps are vital in selecting a reliable supplier, ensuring that the safety clothing provided can withstand rigorous conditions and deliver on its promise of protection.

How to Verify Manufacturer Reputation and Reliability in China

Customer Reviews and Testimonials

When choosing Protective Clothing Suppliers or PPE Clothing Suppliers on platforms like Alibaba, reading customer reviews is very important. Reviews provide insights into product quality, supplier reliability, delivery times, and customer service. This helps businesses make informed decisions. Authentic feedback can highlight potential issues or advantages that might not be obvious from product descriptions alone.

Additionally, customer testimonials and case studies play a significant role in assessing suppliers. Testimonials offer firsthand accounts of customer satisfaction and real-world usage, reinforcing the supplier’s credibility. Case studies provide detailed stories about how the PPE clothing performed in specific situations, showcasing the products’ effectiveness and reliability.

Reading reviews, testimonials, and case studies ensures you choose a supplier who meets safety standards and aligns with your company’s needs and expectations.

Requesting References and Past Performance

When choosing a protective clothing manufacturer, it’s important to thoroughly check potential partners. Start by asking for references and contact previous clients to learn about their experiences with the manufacturer.

Evaluating the consistency and reliability of the manufacturer’s past performance is vital. Look at their history of delivering quality products on time and their adherence to safety standards. Consistency in performance indicates a dependable partner, which is crucial for industries where protective clothing is a key safety component.

By taking these steps, you ensure the manufacturer meets your immediate needs and aligns with long-term quality and reliability standards. This diligence can save time and resources, ensuring you invest in a manufacturer who will consistently meet your protective clothing needs.

Conducting Factory Audits and Third-Party Inspections

Arranging On-Site Visits

1. Preparation:

- Define the Audit: Set the scope and goals, review past reports, and schedule the visit.

- Team Assembly: Gather a team of skilled auditors.

- Checklist Development: Create a checklist for all areas to inspect.

2. Conducting the Audit

- Opening Meeting: Introduce the team, explain objectives, and outline the agenda.

- Facility Tour: Inspect the entire facility, focusing on key areas such as production lines, storage, and quality control stations.

3. What to Look For

- Raw Materials: Check the quality and sourcing.

- Production Processes: Ensure consistency and efficiency.

- Quality Control: See how inspections, defect management, and testing are handled.

- Final Products: Verify they meet specifications and regulations.

- Documentation Review: Check records, certifications, and safety compliance.

- Closing Meeting: Discuss findings, issues, and improvements.

Efficient audits ensure product quality and compliance with regulations.

Utilizing Third-Party Inspection Services

Third-Party Inspections: Hire agencies like SGS, Intertek, TUV, or Bureau Veritas to ensure products meet safety and quality standards.

Benefits:

- Unbiased Assessments: Identify defects and compliance issues.

- Enhanced Safety: Improve product safety and build a strong reputation.

- Detailed Reports: Aid in certification and meeting regulatory requirements.

- Stakeholder Confidence: Assure buyers and users of product standards.

Using third-party inspection agencies helps protect the brand, reduce liability, and ensure high safety standards.

Also, building long-term relationships with reliable suppliers ensures consistent quality, timely materials, better pricing, and improved cost efficiency. Trust and adaptability come from strong partnerships and effective communication. Regular updates, clear contracts, shared metrics, and honest feedback are essential. Technology simplifies communication, and mutual respect solidifies these beneficial relationships.

To choose the right Protective Clothing Manufacturer, understand your needs, ensure products meet safety standards, check supplier reputation, request samples, and review pricing and terms. Consistent communication and regular assessments with your PPE Clothing Suppliers will help maintain high standards. For more guidance, visit our website at morntrip.com or email us at info@morntrip.com.