Table of Contents

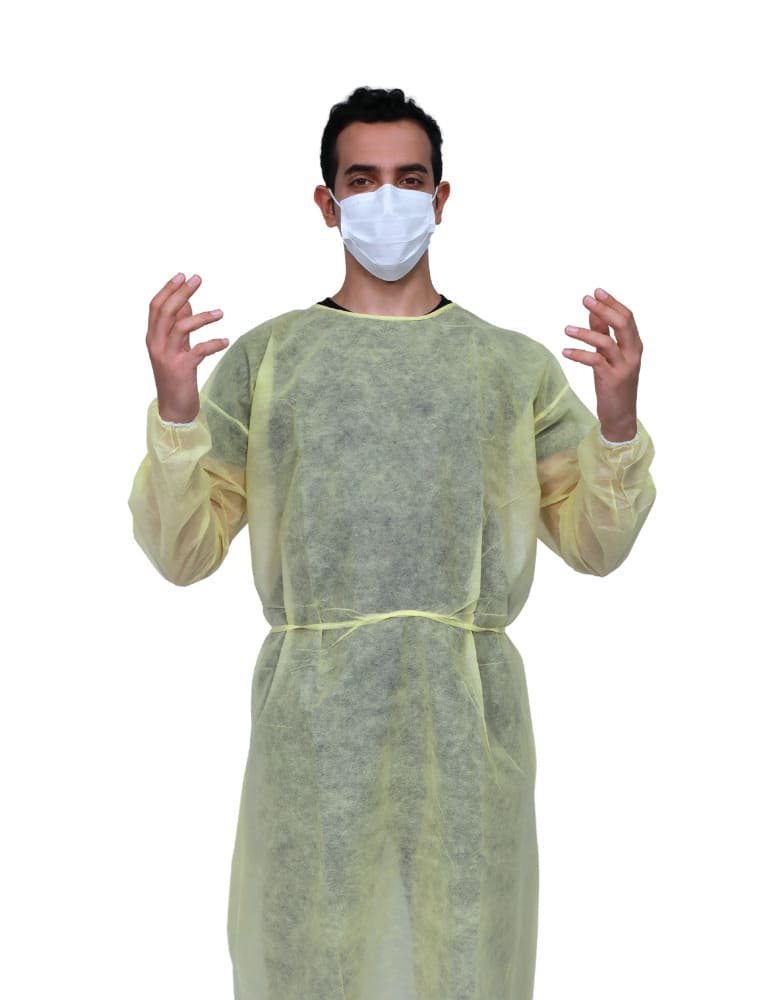

In the fast-moving healthcare industry, disposable medical gowns are vital for keeping patients and healthcare workers safe. (FDA) With global demand on the rise, Medical Gowns Manufacturers are stepping up, focusing on innovation and boosting production. This blog takes a closer look at the medical gown manufacturing industry, covering the market’s current size, future growth, key materials used, and the leading companies driving the sector. If you’re a wholesaler, distributor, or purchasing manager, this guide will help you navigate the ever-changing landscape of medical gown production.

Overview of the Medical Gown Manufacturing Industry

Medical Gowns Market Size and Growth

The global disposable medical gowns market is valued at USD 3,478.3 million in 2024, up from USD 3,235.7 million in 2023. It’s projected to reach USD 7,169.0 million by 2034, driven by a 7.5% compound annual growth rate (CAGR) over the next decade.

This growth is fueled by rising healthcare demands, stricter safety regulations, and greater awareness of infection control in medical settings. As the need for personal protective equipment (PPE) increases, medical gown3 manufacturers are innovating with materials and designs that meet new safety standards while keeping costs manageable. (Accesswire)

Projected Growth of Medical Gowns

Factors driving this growth include increased demand for healthcare, especially during pandemics and disease outbreaks, along with greater awareness of hygiene standards. Manufacturers are responding by developing protective materials and adopting sustainable production methods. This trend highlights a global shift in the importance of PPE, making it a key focus for healthcare systems.

Regional Insights

North America is expected to lead the market due to its strong healthcare infrastructure and strict regulations. Europe and Asia-Pacific are also poised for significant growth. China and India are projected to see CAGRs of 7.5% and 8.5% (Future Market Insights), respectively, fueled by rising healthcare spending and increased focus on patient safety. China’s manufacturing capabilities and India’s growing healthcare sector position them as key players in the global market.

Types of Disposable Medical Gowns Produced by Manufacturers

Medical gowns are primarily categorized into three types: isolation gowns, surgical gowns, and procedural gowns. Each type serves a specific role in healthcare, offering different levels of protection.

Isolation gowns protect healthcare workers and patients from infectious agents. They act as a barrier against infectious droplets or fluids.

Surgical gowns are used during surgeries. They provide higher protection in sterile environments to prevent contamination.

Lastly, procedural gowns are flexible and often worn during non-surgical procedures. They are less restrictive but still help minimize exposure to fluids or contaminants.

Key Materials Used by Disposable Medical Gowns Manufacturers

Polypropylene Medical Gowns

Polypropylene is one of the most widely used materials in disposable medical gowns due to its affordability, versatility, and protective qualities.

Polypropylene gowns are:

- Lightweight and breathable, making them comfortable for extended wear.

- Water-resistant to some extent, which protects against liquid splashes.

- Non-irritating and hypoallergenic, ensuring that they can be worn by individuals with sensitive skin.

However, polypropylene gowns are not completely impervious to liquids and are therefore best suited for low to moderate-risk situations where exposure to bodily fluids or other hazardous materials is minimal.

SMS Medical Gowns

SMS fabric is a composite of three layers—two outer layers of spunbond polypropylene with a middle layer of meltblown polypropylene. This structure gives SMS medical gowns enhanced protective properties while retaining comfort and breathability.

SMS medical gowns offer:

- High fluid resistance, making them suitable for moderate to high-risk environments.

- Effective filtration against bacteria and airborne particles, is critical in infection control.

- Good tensile strength, ensuring that the gown can withstand rigorous use without tearing.

While they are slightly less breathable than pure polypropylene gowns, the balance between protection and comfort makes SMS gowns ideal for situations where both are important.

PE-coated nonwoven Medical Gowns

PE-coated (Polyethylene-coated) nonwoven gowns offer superior protection by combining the breathability of nonwoven fabrics with the impermeability of polyethylene film. This makes these gowns highly resistant to liquids, offering the highest level of protection among the three materials discussed.

PE-coated nonwoven medical gowns provide:

- Maximum fluid and contaminant resistance, which is crucial in high-risk environments.

- Full impermeability, making them ideal for procedures involving high exposure to fluids.

- Durability, ensuring they don’t tear or puncture easily during use.

Comparative Analysis of the Three Materials

| Feature | Polypropylene (PP) | SMS (Spunbond-Meltblown-Spunbond) | PE-coated Nonwoven |

|---|---|---|---|

| Breathability | High | Medium | Low |

| Fluid Resistance | Low to Moderate | Moderate to High | High |

| Comfort for Extended Use | High | Moderate | Low |

| Bacterial Filtration | Low to Moderate | High | High |

| Durability | Moderate | High | Very High |

| Cost | Low | Moderate | High |

| Typical Applications | Low-risk environments | Medium-risk environments | High-risk environments |

Leading Global Medical Gowns Manufacturers in the Industry

Cardinal Health is a leading healthcare services and products company, supplying a wide range of medical products, including disposable medical gowns. The company is known for its innovations in infection control and safety solutions.

- Main Products: Medical gowns, surgical gloves, and infection control products.

- Base City: Dublin, Ohio, USA

- Year Established: 1971

- Certifications: ISO 9001, FDA registered

2. 3M

3M is a global science company that develops innovative solutions across various industries, including healthcare. Their medical gowns and personal protective equipment (PPE) are widely used in healthcare environments worldwide.

- Main Products: Surgical gowns, respirators, medical tapes, and PPE.

- Base City: St. Paul, Minnesota, USA

- Year Established: 1902

- Certifications: ISO 9001, FDA registered

3. Medline Industries Inc.

Medline Industries is one of the largest privately-held manufacturers and distributors of medical supplies globally. The company provides a wide array of medical gowns designed for different levels of protection and comfort.

- Main Products: Surgical gowns, isolation gowns, and drapes.

- Base City: Northfield, Illinois, USA

- Year Established: 1910

- Certifications: ISO 13485, FDA registered

4. Aspen Surgical Products

Aspen Surgical is a trusted manufacturer of medical devices and products, with a focus on improving safety and efficiency in healthcare. The company produces high-quality surgical and isolation gowns.

- Main Products: Surgical gowns, drapes, and medical disposables.

- Base City: Caledonia, Michigan, USA

- Year Established: 1999

- Certifications: ISO 13485, FDA registered

5. Halyard Health

Halyard Health, part of Owens & Minor, is a leading global provider of healthcare products focused on infection prevention. Their medical gowns meet stringent safety standards for protecting healthcare professionals.

- Main Products: Surgical gowns, sterile drapes, and PPE.

- Base City: Alpharetta, Georgia, USA

- Year Established: 2014 (spun off from Kimberly-Clark)

- Certifications: ISO 13485, FDA registered

The medical gown manufacturing industry is growing due to increasing demand, especially in healthcare and surgical settings. Manufacturers produce various types of gowns, including disposable, reusable, isolation, and surgical gowns, each designed for specific protection and comfort levels. The market is shifting towards eco-friendly and durable materials, with innovations like antimicrobial fabrics and fluid-repellent textiles gaining popularity. Leading manufacturers follow strict FDA and CE standards, setting benchmarks for the industry. Choosing reliable suppliers and keeping up with material advancements is crucial to ensure safety, cost-effectiveness, and compliance with industry standards.

As a distributor or bulk buyer, your success depends on finding reliable medical gowns manufacturers who deliver quality, compliance, and consistent production. Partner with Morntrip to access manufacturers who offer stable pricing, on-time delivery, and the flexibility to meet your growing demands. Don’t let supply chain issues impact your business. Contact us today to secure a dependable source for your medical gown needs and stay ahead in the competitive healthcare supply market.